Quality Wednesdays: How we trained our team to see what doesn’t work

In early 2023 at an offsite in Tenerife, our European engineering team did a series of exercises that ended up changing the way we work.

The first was a test of sorts. I showed the team a short screen recording of a small part of the Linear app: a series of three buttons, each illuminating when the mouse hovered over them and going dark when the mouse moved away. I asked the team if they could tell what was wrong with the interactions. Even after watching it a few times, no one could see it. That’s when I realized we probably weren’t looking at the right things.

That same afternoon we did a more open-ended survey. One by one we scrutinized specific parts of the application like display options and issue lists. I gave the team the prompt to write down everything they noticed that wasn’t quite as good as it could have been. I didn’t know whether we’d turn up a long list or barely notice anything at all. Even so, I was surprised by the outcome: Each person noticed something different—small quality flaws that had been invisible to everyone else, including me.

From these offsite experiences, two things became clear. The first was that the pursuit of quality is not an individual sport. It’s hard to perceive subtle problems with a UI you yourself have built. Other people need to point out problems, and if you do it as a group, you’ll come closer to gaining a comprehensive view of everything that’s wrong with a product.

The second thing I realized is that I wanted a way to make sure we kept quality top-of-mind in everything we did. At the same time, I knew the team was too busy to drastically reallocate how we were spending our time. We needed quality to be a habit, like brushing your teeth. Something you just do without thinking too much about it. No one ever says they don’t have time to brush their teeth. I wanted our team to begin thinking about quality in the same way.

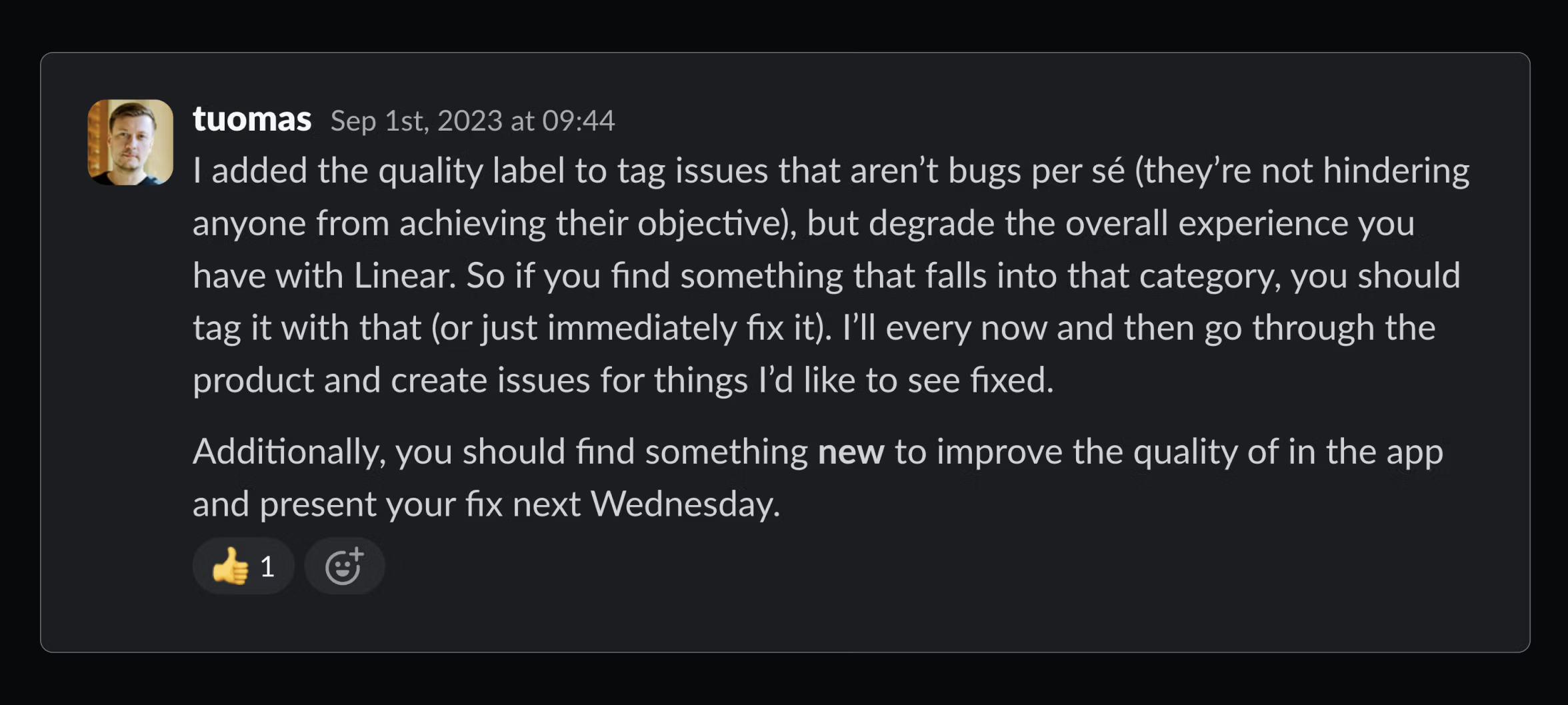

A new practice came out of that offsite, which we formalized a few weeks later. In my announcement I asked that each engineer find and fix some defect that’s decreasing the overall quality of the app. I added that these fixes shouldn’t address “bugs per se,” but rather, small imperfections that “degrade the overall experience you have with Linear.” I asked the team that we henceforth devote our Wednesday team meeting (one of three standups we have each week) to presenting our quality fixes. That was the start of a ritual we now call Quality Wednesdays. It’s been going ever since.

Making quality a habit

Everyone on the team approaches Quality Wednesdays in their own way. One engineer maintains a note file where he records everything he encounters during the week that seems off to him. Then as Quality Wednesday approaches, he’ll fix one or two. Others make quality fixes in the natural course of their work.

There is no shortage of places to look. Some people make quality fixes on a theme. They’ll spend a month or two scouring the menus in “Preferences,” or looking at keyboard navigations or accessibility features. The way the product appeared on mobile was a popular hunting ground before we had a native mobile app. Not all controls were optimized for small spaces, so often you could find a quality fix just by narrowing your browser and seeing what didn’t look right.

Here is a fix from this June that standardized the sizes of adjacent buttons:

And here’s a recent UX fix to stop the height of the issue composer from changing when the user adds a line:

Many of these quality fixes take 30 minutes or less. None should take more than an hour or so. Keeping the time commitment low helps to make it a sustainable practice. Consistency matters a lot too. It’s not strictly speaking a requirement that each engineer make a quality fix each week. But if someone misses a week, I’ve been known to joke, “That’s OK, just bring two next week.” The point is that attention to quality only works when it’s a habit, and as with any habit, it’s easy to lose momentum if you miss a rep.

Catching mistakes before they happen

Over the last two years we’ve completed more than 1,000 small acts of polish as part of Quality Wednesdays; we track them inside Linear with a “quality” label.

Most of these fixes are small on their own, but together they completely change how the product feels. They allow us to push Linear’s extremely high quality bar even higher.

These 1,000+ improvements are also just one part of the impact Quality Wednesdays has had on our team and on the product. The bigger change is in how we build new things in the first place. This is how one engineer on the team put it recently: “Since you train this muscle over time, you start noticing patterns and common pitfalls while building stuff, so fewer of these papercuts ship.”

On that point, I think about that screen recording I showed the team more than two years ago, of the mouse hovering over three buttons. The problem with it—the one that the team couldn’t see at the time—was that the animations were inconsistent: one of the buttons darkened instantly when the mouse moved away, rather than fading out over 150 milliseconds as it should have.

I think everyone on the team would catch that now. But more importantly, because of Quality Wednesdays, it’s also far less likely to arise.